Pres-Vac Engineering

Detonation Arresters

Closed piping or manifold tank systems normally include sizable lengths of vent piping. The bend, and elbows and other changed of section. These systems require detonation arrestors to mitigate the danger of flames transitioning to a high-speed deflagration and detonation on board vessels.

What is a detonation arrestor?

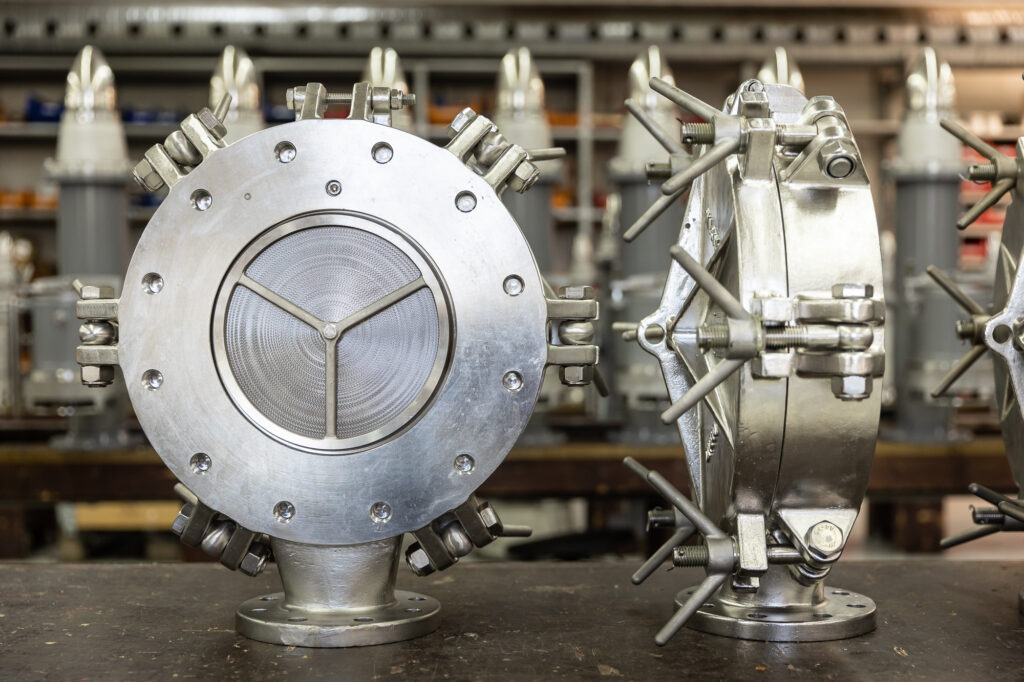

A detonation arrestor – also referred to as a detonation flame arrester – is a critical safety device designed to prevent flame transmission and high-pressure shockwaves from propagating through vent lines or gas return systems. At Pres-Vac Engineering, we offer certified solutions tailored to the demanding conditions on board tankers and marine vessels. Our JS-2370 and VOR-2385 models provide full detonation protection, including inline endurance burning and stabilized flame resistance, while maintaining compact dimensions suitable for confined installation environments.

Superior performance and easy maintenance in gas return lines

Pres-Vac detonation flame arresters are engineered for performance and serviceability. The integrated flame barrier absorbs and quenches flame energy, halting detonation waves traveling at speeds up to 1,850 m/s and pressures up to 35 bar. Designed for minimal pressure drop, our arresters allow unrestricted gas flow while maintaining full safety compliance with IMO, EU-MED, and ADN standards. With a removable flame element and no need for cranes or special tools, routine maintenance can be performed by a single crew member – reducing both downtime and costs.

The JS 2370 and VOR-2385 Detonation Arrestor

In-line detonation arrester type JS 2370 and VOR-2385, which is also suitable for end-of-line installation, is designed to prevent flame fronts in pipe lines from passing through but allows non-burning gases to continue. Due to its compact size and low weight it is ideal for marine gas return systems.

Type JS is fully approved for AND, EU-MED and IMO vessels.

Specifications and testing

Designing, testing and using of detonation arresters is a complex matter involving consideration for pipe configuration, location, operational conditions, physical properties of gases and vapors and pressure drop limitations.

Type JS will restrain fire from passing in case of deflagration and detonation and can be installed anywhere in the piping. It features easily removable flame traps and can be maintained by a single service engineer without need for special tools, lifting crane etc. Certain limitations in application must be observed and thorough consulting is advised.

Design

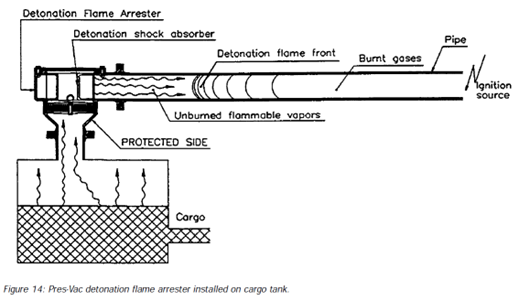

As illustrated in figure 14, this type of detonation flame arrester offers prevention of flashback in case of explosion and detonation on one side and prevention of explosion on the other. Therefore, the possible source of ignition always has to be located on the side with the detonation shock absorber.

The turnover point from deflagration to detonation is reached when the unburned gases are compressed to autoignition temperature and consequently burn as a detonation, even though it has not been in contact with the flame front. At this point a peak velocity of more than 4,500 m/sec. and short time static pressure of more than 100 bar can be reached, steadying at a constant velocity of approximately 1,850 m/sec. and 35 bar.

Technical Comparison: JS-2370 vs. VOR-2385

| Feature | JS-2370 | VOR-2385 |

|---|---|---|

Design | Compact detonation flame arrester with built-in connections | Modular detonation flame arrester with separate housing and insert |

| Best suited for | Applications with limited installation space | Applications where easy replacement of the flame insert is prioritised |

| Connection type | Weld neck flange | Loose flange with welding ends or other custom ends |

| Mounting orientation | Flexible: horizontal and vertical | Typically horizontal (can be customized) |

| Serviceability | Service without removing unit from pipe system | Requires more space but offers easier insert replacement |

| Weight | Lighter, space-saving design | Heavier, more robust construction |

| Customization | Standardized sizes | Available with custom flange dimensions/materials |

| Common use cases | VOC return lines, tank venting with space constraints | Larger pipe systems, where modular service is preferred |

FAQ – Frequently asked questions

Find an answer to the most frequently asked questions about detonation and flame arresters.

What is the difference between a detonation arrestor and a flame arrester?

A flame arrester protects against low-speed deflagrations, while a detonation arrestor is built to stop high-speed detonations and pressure shocks, making it essential for marine gas return systems.

Can Pres-Vac’s detonation flame arresters be installed in any position?

Yes – both JS-2370 and VOR-2385 are designed for versatile in-line or end-of-line installation. They are fully symmetrical and operate independently of flow direction

What certifications do your detonation flame arresters meet?

Our arresters are approved according to IMO standards, EU-MED, and ADN, ensuring full compliance with global marine safety regulations.

Why is pressure drop important when choosing a detonation arrestor?

Low pressure drop ensures optimal ventilation flow and efficiency in gas return systems, minimizing strain on connected equipment.

How often should a detonation flame arrester be serviced?

Service intervals depend on usage, but thanks to the removable flame element, inspection and cleaning are straightforward and can be handled onboard without external support.

Request a quote

By filling out this form, your request will be shared directly with our experts. We will reply as soon as possible.