Static Flame Arresters

Our Static Flame Arresters series are made with the strictest IMO standards in mind, offering the highest possible safety standards and unsurpassed operational performance. These flame arresters provide protection against the passage of flames should a fire occur on board, while securing that gas emissions are kept at a minimum.

A static flame arrester – also referred to as a flame screen, flame trap, or flame arrestor screen – is a passive safety device designed to stop flame propagation in vent and gas piping systems. It works by absorbing and dissipating heat through a finely engineered mesh or perforated matrix, effectively extinguishing the flame front before it can enter a tank or pipeline. Static flame arresters are essential in marine applications where volatile gases must be safely vented without risk of ignition.

Pres-Vac’s flame arresters are certified to meet international marine safety standards and are built for harsh conditions on tankers, gas carriers, and VOC systems. With minimal pressure drop and robust weather protection, these arresters ensure continuous operation even in demanding offshore environments.

Available in three versions

Type EFA-E

The EFA-E end-of-line deflagration endurance burn proof flame arrester is developed for seagoing and inland tanker vessels.

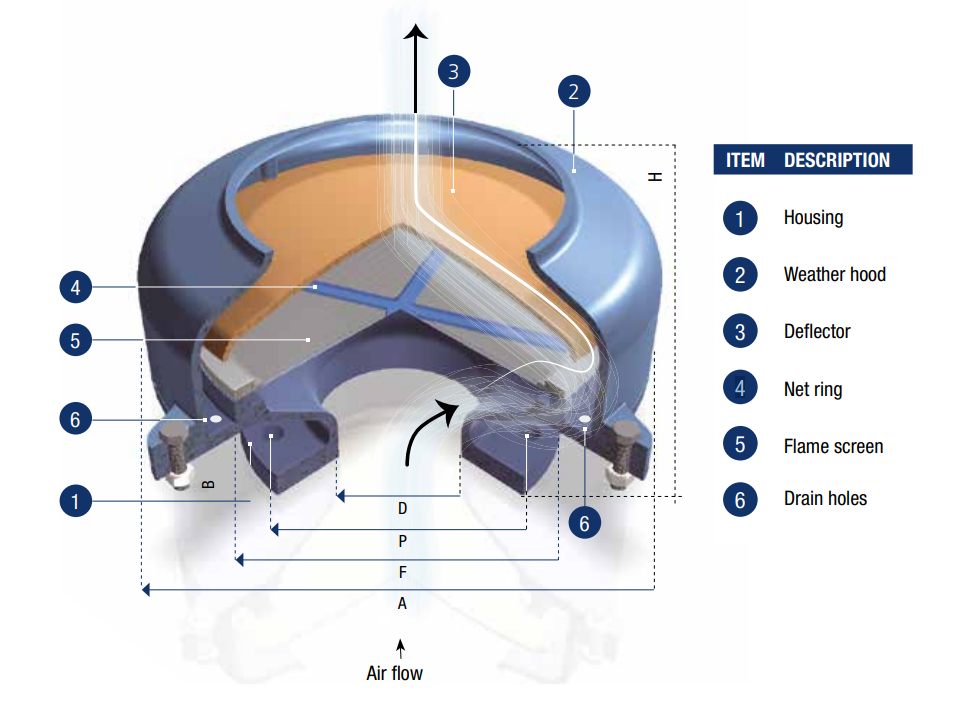

Type EPV

The EPV vertical, end-of-line flame arrester is ideal for small and medium capacities.

Type VFA

The VFA flame arrester is ideal for versatile cargoes and small to medium capacity applications. Applicable for oil tankers and old-fashioned common venting systems

Flame Arrester Valves and Breather Valves with Flame Screens

Flame arresters can also be integrated into pressure/vacuum valves to create a compact solution that combines overpressure protection and flame arresting in one unit. This type of flame arrester valve or breather valve with flame screen is ideal for installation on tank vents and VOC return lines. By preventing flashback while regulating tank pressure, they offer dual functionality and help meet safety and emission compliance.

Pres-Vac offers several static flame arrester types – including the EFA-E, EPV, and VFA – each designed for specific flow requirements and installation setups. Whether for high-flow venting, compact installations, or retrofits, there is a suitable configuration available.

Type EPV

Benefits

Our venting equipment can be optimised to meet your requirements

Maximum safety for crew, vessel and cargo

- Designed to prevent passage of flame

- Equipped with weather hood to open in case of fire.

- Certified to withstand flame transmission during endurance burning.

Compliance with all current and foreseen regulations

- No risk of non-compliance

- Complies with the latest European standard for fire testing

Excellent operational performance

- Efficient drainage of rain water, condensation and water from cleaning

- Flame screen protection against snow and ice

- Stable function during voyage regardless of thermal variation and sloshing

Low maintenance costs

- Replacement of spare parts is cost efficient due to simple design

- Handy removal for inspection and cleaning

- Maintenance kit available for easy replacement by crew

- Lifetime availability of spare parts and a global network of service centres.

Specifications

- Simple and rigid design with low pressure drop.

- Flame screen protection.

- Flame screen with 0.65 MESG – Apparatus group IIB

- Drainage holes to drain off water.

- Weather hood to protect from splashing of sea water and rain.

- Available from DN50 to DN300 flange diameter and multiple flange standards.

- Maintenance of few parts only.

- Easy access for service of unit.

Safety and Compliance

The marine sector is restricted by several rules and regulations stipulated by leading classification societies. The EPV valve has been subjected to severe tests in order to meet these market demands for high quality and safety.

All of our valves have completed vigorous testing to ensure the safest voyages for crew and cargo.

The EPV Valve is approved in accordance with IMO/Circ. 677 amended MSC/Circ. 1324, EN16852:2016 and EU-MED. The type is also approved by major classification societies.

Type EFA-E

Benefits

The equipment can be optimised to effectively meet your venting requirements.

- Ideal for both inland and seagoing tanker vessels

Maximum safety for crew, vessel and cargo

- Designed to prevent passage of flame.

- Equipped with weather hood to open in case of fire and protect from the rain.

- Certified to withstand flame transmission during endurance burning.

Compliance with all current and foreseen regulations

- No risk of non-compliance

- Complies with the latest European standard for fire testing

Excellent operational performance

- Efficient drainage of rain water, condensation and water from cleaning

- Flame screen protection against snow and ice

- Stable function during voyage regardless of thermal variation and sloshing

Low maintenance costs

- Lifetime availability of spare parts and a global network of service centres.

Features and specifications

- The EFA-E is designed to prevent the passage of flame if a fire should occur.

- The device is certified to withstand flame transmission during endurance burning.

- EFA-E is available for Explosion group IIB (MESG ≥ 0.50mm) requirements and alcohols.

- The device is equipped with a weather hood which will open in case of fire.

- The EFA-E is type approved in accordance with ATEX directive and EN ISO 16852. In addition, it is approved to comply with IMO/MSC/Circ. 677 – 1009 and IMO/MSC/Circ. 1324 & 1325.

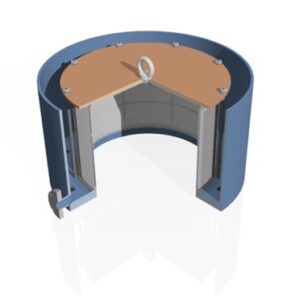

Type VFA

Benefits

Ideal for Versatile Cargoes

- Gas outlet area can be adjusted without limits to prevent oil mist above deck

- Designed for high capacity applications and old-fashioned common venting systems

- Fully approves for exclusively inerted vessels and for Apparatus group IIA and IIB

Maximum safety for crew, vessel and cargo

- Designed to prevent passage of flame

- Features adjusted to your vessel to be sure of full safety, independent on crew routines

- The flame screen unit is easily removable to enable frequent inspection and cleaning as may be needed depending primarily on inert gas quality.

Compliance with all current and foreseen regulations

- No risk of non-compliance

- Complies with the latest European standard for fire testing

Excellent operational performance

- Efficient drainage ports that are connectable to collection facilities

- Flame screen protection against snow and ice

Low maintenance costs

- Lifetime availability of spare parts and a global network of service centres.

Our venting equipment can be optimised to meet your requirements

VFA – Vertical Efflux Flame Screen

Type VFA features extreme low pressure drop and is designed for high capacity applications such as oil tankers with old-fashioned common venting systems. For applications with highly volatile crude – typically shuttle tankers where pressure control valve type N is used – type VFA features adequate drainage ports that are connectable to collection facilities.

The typical installation where a high capacity flame screen is used will feature either small breather valves on each tank (common venting) or full sized high velocity vents on each tank for full safety independent on crew routines (individual venting).

Consequently, the flame screen is not the source of relief for thermal variation or sloshing. When selecting the right size of flame screen, the most important aspect is a careful pressure drop calculation according to IMO MSC/Circ.731 to ensure that the p/v valves do not operate prematurely or cause excessive leakage.

VFA Features

- IMO approved as explosion safe

- Compact size compared to capacity

- Efficient drainage for high vapor pressure crude

- Easy maintenance

- Simple and rigid design

- Adjustable net clearance to reduce oil mist formation

FAQ – Frequently Asked Questions

Here you will find the most frequently asked questions and answers regarding flame arrestor and flame screens.

What is the difference between a flame screen and a flame arrestor screen?

A flame screen is the internal mesh element within a static flame arrester that quenches flames. “Flame arrestor screen” typically refers to the same component but emphasizes its role in extinguishing flame propagation according to safety standards.

Can a breather valve include a flame arrester?

Yes, many breather valves are available with integrated flame arresters. These combined units regulate tank pressure while also protecting against external ignition sources.

What certifications apply to flame arresters?

Pres-Vac flame arresters meet international standards including IMO, EU-MED, and EN ISO 16852, and are suitable for use with Group IIB gases.

What is the purpose of a flame trap?

A flame trap prevents flame from traveling back through a vent or pipe by cooling and extinguishing it. It acts as a safety barrier between potential ignition sources and volatile vapors

How do you maintain a flame screen?

Flame screens should be inspected regularly for contamination or blockage. Pres-Vac’s designs allow the mesh to be removed and cleaned without special tools, making onboard maintenance fast and efficient.

Contact us

By filling out this form, your request will be shared directly with our experts. We will reply as soon as possible.