Vacuum pressure control valves: Ensuring safe tanker operations through precise pressure management

Effective management of pressure within cargo tanks is mission-critical for tanker safety and operational reliability. Understanding the distinction between relief valves and vacuum pressure control valves is essential for ensuring crew safety, cargo integrity, and full compliance with IMO and ISO standards.

Relief valve vs. vacuum pressure control valve: What is the difference?

Relief valves are safety devices designed to protect tanks from overpressure or excessive vacuum by opening momentarily to “relieve” pressure once preset limits are reached. They serve as a last line of defence, preventing catastrophic failure or structural damage.

In contrast, a vacuum pressure control valve – also known as a pressure vacuum control valve – is engineered for continuous, precise pressure regulation. Rather than only responding in emergencies, control valves actively stabilise internal tank pressure throughout loading, sailing, and discharge. This proactive control protects both crew and vessel by mitigating risks before they escalate.

How vacuum pressure control valves stabilise tank pressure

During loading, unloading, and transit, internal tank pressures fluctuate due to temperature changes or cargo movement. The control valve dynamically adjusts to these changes, maintaining the desired set point. This prevents both overpressure (which can compromise tank integrity) and vacuum (which can lead to implosions).

The result is reliable protection for both the crew and the cargo, supporting safe working conditions and ensuring the transported product remains uncompromised.

Safety, cargo integrity, and compliance

- Crew Safety: Stable tank pressure minimises the risk of hazardous incidents, contributing to safer onboard environments.

- Cargo Integrity: Precise control prevents contamination and damage, safeguarding valuable cargo throughout the voyage.

- Regulatory Compliance: Our vacuum pressure control valves are compliant with IMO MARPOL and ISO requirements, ensuring adherence to international safety and environmental standards.

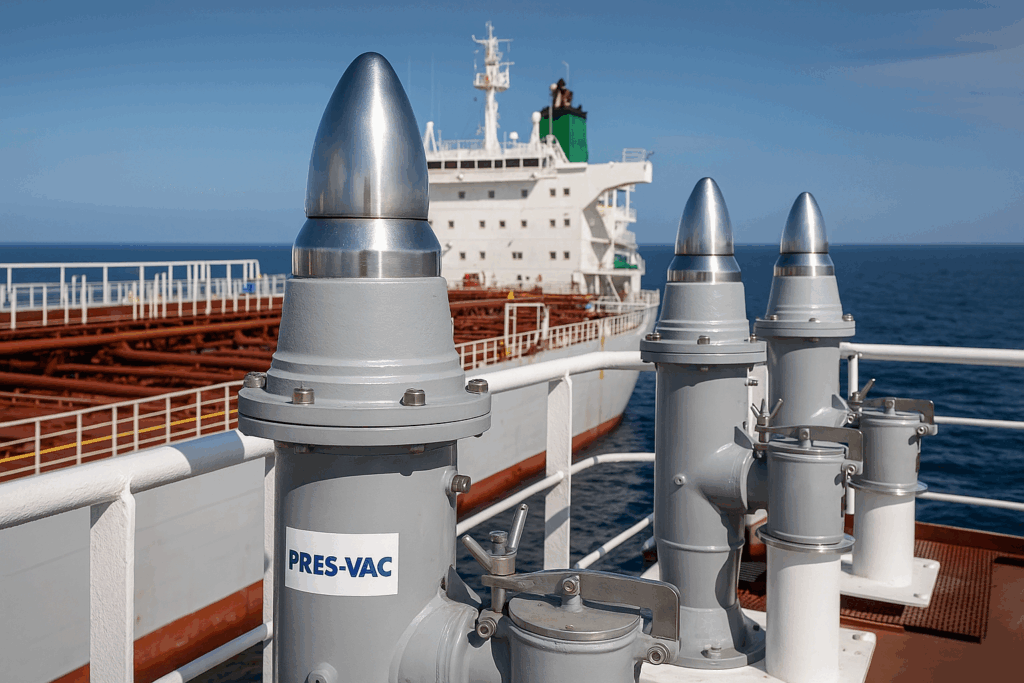

Pres-Vac: Documented solutions for pressure and vacuum control

As part of G&O Maritime Group, Pres-Vac is recognised for industry-leading, non-hammering valve designs that minimise operational noise and wear while ensuring optimal performance. Pres-Vac’s dual-system solutions offer redundancy and flexibility for evolving operational profiles. All valves, including our vacuum pressure control valve models, are rigorously tested and certified, supporting customers in achieving complete compliance – regardless of their global trade routes or cargo types.

For enhanced safety, our flame arrester solutions can be integrated to protect tank atmospheres from ignition risks. This combination of vacuum pressure control valves and flame arresters is particularly relevant for vessels operating under IMO 1621, ISO 15364 and ISO 16852 standards, ensuring not just compliance – but optimal safety under real-world conditions.

The vacuum pressure control valve plays a crucial role in maintaining safe conditions during loading, unloading, and voyage, as tank pressure can fluctuate due to temperature changes, cargo movement, or inert gas variations. Our magnet-controlled valve designs offer fast blow-down performance and eliminate pressure oscillations – even on long vent pipes – reducing the risk of emissions, mechanical wear and crew exposure.

Pres-Vac Engineering is trusted by shipowners and operators worldwide for its unrivalled expertise in pressure and vacuum safety. With more than 70 years of experience and certified solutions tailored to methanol, ammonia, oil and chemical cargoes, we support the global fleet in achieving safer, cleaner, and more efficient operations.