Ensuring Safety and Compliance in Maritime Industry with High-Speed Valves

Never compromise on safety. A fully loaded tank or chemical ship is vulnerable, and the potential consequences of pressure variations or fire in a tank are unimaginable.

To safeguard crew, ship, and cargo to the fullest extent possible, regulations regarding these aspects are constantly discussed within the IMO, EU, and ISO. The EU is at the forefront of ratifying rules, currently utilising ISO standards in addition to IMO rules for testing and approving high-speed valves.

Rules from IMO, EU-MED, and USCG are employed to test and determine the quality of high-speed valves today. Specific applications such as offshore constructions, inland tankers, and dual-fuel ships utilising Methanol, Ammonia, and Hydrogen as fuel also have their set of regulations. Current standards and rules include requirements for shipowners and shipyards to carefully select high-speed valves, ensuring they are “suitable for the service intended,” as described by ISO15364. ISO15364 also outlines the characteristics that the selected valve installation must fulfill.

In 2000, Pres-Vac Engineering presented a solution, a modern high-speed valve, to meet the regulations of that time. This valve ensures that the ship is not damaged by over- or under-pressure in the tanks, prevents flame propagation in case of a deck fire, and minimises the release of vapors from the cargo, protecting the crew and the environment. Moreover, these valves operate without adding pressure to the cargo tanks, making it easier to optimise their size for the ship’s cargo operation.

“While a racing bike operates at around 4 barg pressure in its tires, we must remember that a ship’s cargo tanks today should not be subjected to an overpressure of more than 0.25 barg. So even a small overpressure in a cargo tank can cause damage. On the underpressure side, it’s even more stringent as a cargo tank must not exceed 0.07 barg underpressure/vacuum,” says Pres-Vac Sales Manager Jens Reimer.

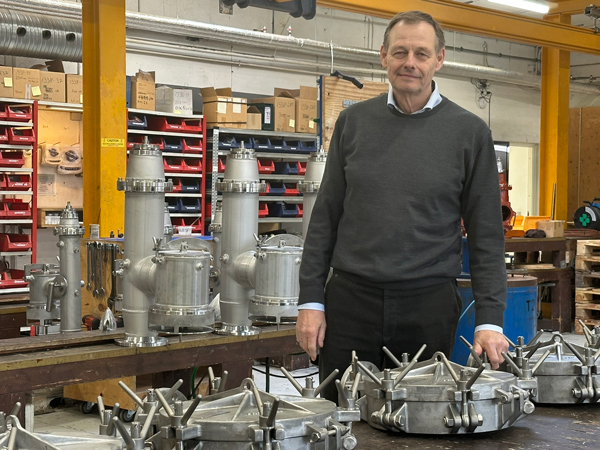

Since the introduction of the first regulations, Pres-Vac has worked diligently and stands strong with the right products, currently being the market leader in high-quality valves for offshore, tank, and chemical ships.

In today’s market, three types of high-speed valves exist

One solution is weight-controlled, where a weight controls the opening and closing of the valve. These valves work with overpressure in the opening phase and face a challenge when the opening pressure is close to the permissible limit, as on a chemical ship.

Another solution is magnetically controlled opening. These valves do not have overpressure when opening but tend to close late, leading to emissions.

“Our valves are developed to avoid overpressure, they have a ‘breather’ function that keeps the pressure on the cargo, to avoid it ‘boiling off,’ and they close early to minimise gas emissions from the cargo. We introduced the soft seal that works in conjunction with the hard seat to create a nearly leakage-free valve under the current rules and to minimise wear on the hard seat. Additionally, since we work with weight and magnet control, we can adjust the valve characteristics to fit the specific ship,” Jens Reimer explains.

The new market for high-speed valves

The emerging era of ‘dual-fuel’ signifies ships being built or retrofitted for methanol, ammonia, or hydrogen as fuel. Tanks storing these fuels must, according to new regulations, be protected by “devices to prevent the passage of flame,” best achieved by installing high-speed valves. The inline solution can also be equipped with end-of-line protection for high efflux velocity.

The challenge with these new fuel systems is that venting pipes from methanol tanks to ventilation can be up to 100 meters long. Since valves must be tested and approved under the conditions they will be used, the valve must be tested on the same length of pipe.

“It requires a solution where the valve performs the task with great precision, and we have that solution too. Our latest design, the PV-ECO model, has been thoroughly tested and works flawlessly on very long pipes,” concludes Jens Reimer.

-

PV Breaker vs PV Valve on Ships

-

Vacuum Pressure Relief Valves for Tanker Safety

-

Vacuum Pressure Control Valves for Safe Tanker Operations

-

Breather valves with flame arrestors: Dual protection for safe tanker operations

-

White paper: The dual fuel venting systems requirement & solution for small vessels

-

Pres-Vac sets the standard for the valves of the future

-

Newly released revision of the IMO/677 concerning high velocity pressure vacuum valve.

-

What is a Pressure Vacuum Valve? Ensuring Tank Safety and Compliance at Sea

-

Redefining Safety and Efficiency in Tanker Valve Solutions

-

Understanding Pressure Vacuum Valves

-

New certification for High-Velocity Valves: Safety and flexibility for the future of Methanol-Fuelled Vessels

-

White Paper: THE DUAL-FUEL SOLUTION

-

Dual-fuel shipbuilding advances through strict certification of methanol valves

-

Tailored Solutions for the Chinese Maritime Market

-

Ensuring Safety and Compliance in Maritime Industry with High-Speed Valves

-

White Paper: Pres-Vac venting valves for methanol storage

-

Pres-Vac Visits Silicone Valley

-

Pres-Vac Engineering celebrating 70th anniversary

-

The Pres-Vac Promise

-

Pres-Vac Vaccum-M Valve

Contact us

By filling out this form, your request will be shared directly with our experts. We will reply as soon as possible.